In-Stock Products

Showing 1–12 of 40 results

Air Handling Unit

The basic function of the air handling unit is take in outside air, recondition it & supply it to the required place. Depend on the requirement a filtration level, pressurization pressure, temperature & R.H. level can be set. A AHU/ASU is to keep the booths, FOZ & painting are dust free & pressurized so that dust particle do not enter in the painting area & good quality output can taken out.

Except dust level, temperature & humidity also play a role for painting quality.

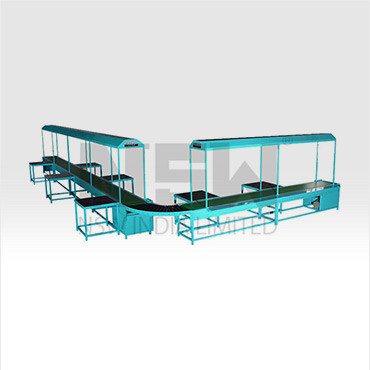

SEND ENQUIRYAutomation

The basic function of the air handling unit is take in outside air, recondition it & supply it to the required place. Depend on the requirement a filtration level, pressurization pressure, temperature & R.H. level can be set. A AHU/ASU is to keep the booths, FOZ & painting are dust free & pressurized so that dust particle do not enter in the painting area & good quality output can taken out.

Except dust level, temperature & humidity also play a role for painting quality.

SEND ENQUIRY